p-Phenylenediamine with CAS 106-50-3

Para-phenylene diamine (p - Phenylenediamine), also known as ur silk D, is one of the most simple aromatic diamine, is also a kind of widely used intermediates, can be used for preparing the azo dyes, polymers, also can be used in the production of fur dyeing agent, rubber stabilizer and photo developer, para-phenylene diamine or other commonly used inspection iron and copper sensitive reagents. P-phenylenediamine is a very important dye intermediate, mainly used in aramid, azo dyestuff, sulfide dyestuff, acid dyestuff, etc.

CAS:106-50-3

MF:C6H8N2

MW:108.14

EINECS:203-404-7

Synonyms:benzofurd ;C.I. 76076;C.I. Developer 13;C.I. Oxidation Base 10;c.i.developer13 ;c.i.oxidationbase10 ;C.I.OxidationBase10(76060) ;cideveloper13

Properties

Melting point:139 °C

Boiling point:267 °C(lit.)

Density 1.135 g/cm3 (20℃)

vapor density 3.7 (vs air)

vapor pressure 1.08 mm Hg ( 100 °C)

Flash point:156 °C

storage temp. 2-8°C

solubility Soluble in alcohol, chloroform, ether and hot benzene.

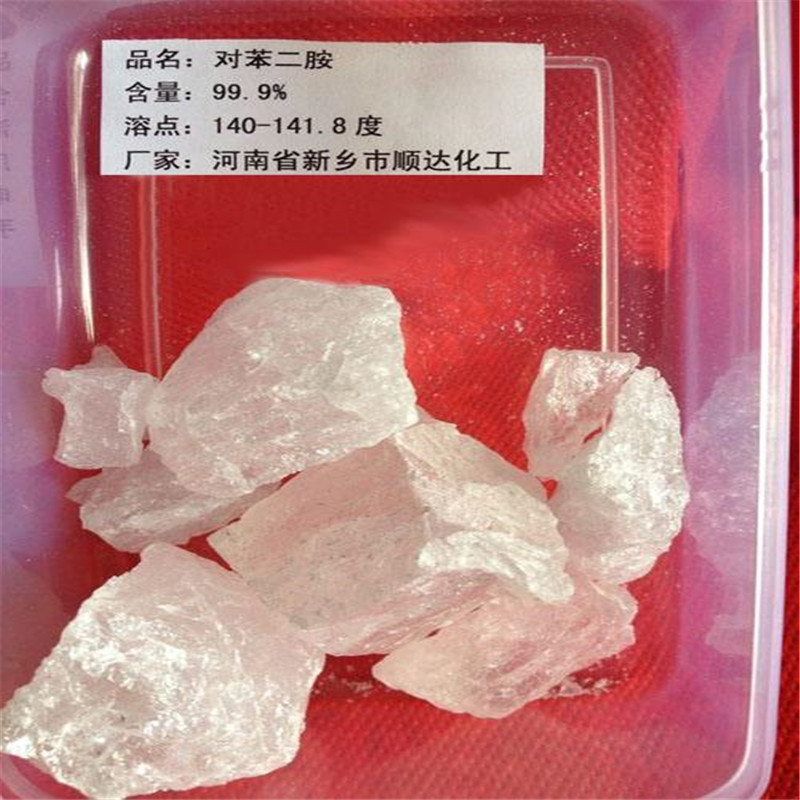

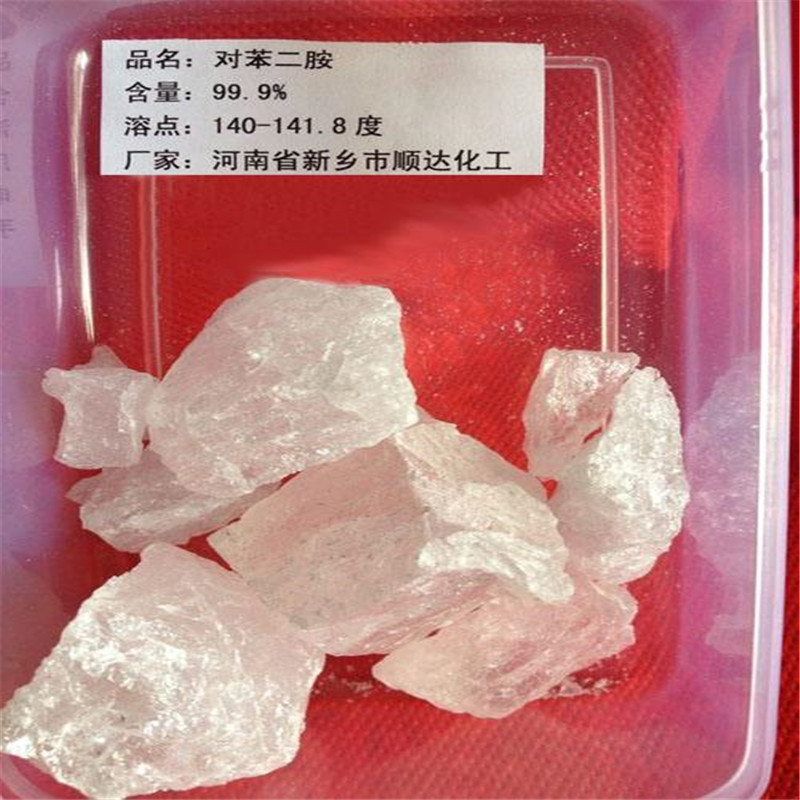

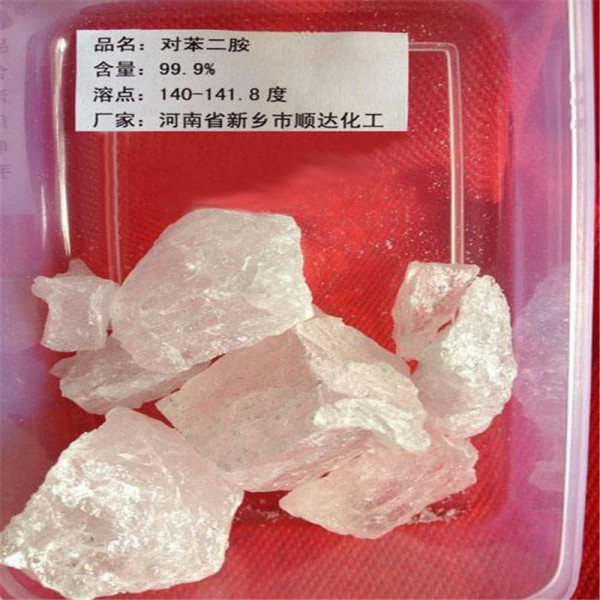

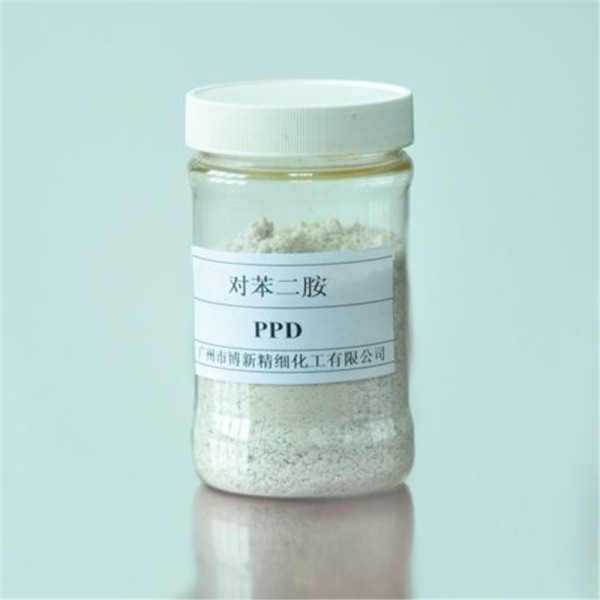

form Powder or Flakes

pka4.17(at 25℃)

Colour Index 76060

color White, gray, or purple to brown

PH RangeNonQ uorescence (3.1) to orange/yellow Q uorescence (4.4)

PH 9 (50g/l, H2O, 20℃)

Water Solubility 47 g/L (25 ºC)

Merck 14,7285

BRN 742029

Stability:Stable, but oxidizes when exposed to air. Incompatible with oxidizing agents. Store under inert atmosphere.

Use

Synthetic dyes and pigments

P-phenylenediamine is the intermediate of azo disperse dyes, acid dyes, direct dyes and sulfide dyes. Add 3% hydrogen peroxide to make it dark, and 5% iron chloride to make it brown. It has a strong affinity for keratin in hair, and its oxidation process is the fixation of color when dyeing hair. It is not only the most effective component of hair dye, but also the most potentially harmful substance to human health.

In the 1980s, according to the CI, 17 varieties were using p-phenylenediamine.

Sulfide yellow GC (CI 5310) originally used diphenylamine as an intermediate, because of carcinogenesis, xinbin county chemical plant has been successfully substituted with p-phenylenediamine. P-phenylenediamine derivatives 4.4' -diaminodiphenylurea and 4.4' -diaminodiphenylurea can also be used in other diazo dyes using diphenylamine instead of diphenylamine (synthesized from p-phenylenediamine, urea and thioneuria).

P-phenylenediamine can also be used to synthesize diazo condensation pigments, such as PR 166(Cr Scarlet R) and green sulfide dyes.

In addition, it can also synthesize better dyeing and pigment.

Synthetic resin

Kevlar 1414 (dupont Kevlar) is made from terephthalic acid or acylchloride by condensation with p-phenylenediamine. Domestic chenguang chemical research institute has an annual yield of 3-5 tons of resin pilot plant, yueyang general factory also has an annual output of 20 tons of resin pilot plant. In 1975, dupont also developed the polyimide resin nr-i50b2, which was formed by condensation of hexafluorotetraic acid and mixed aromatic diamine (4.4' -diaminodiphenyl ether, p-phenylenediamine and m-phenylenediamine). The polyamide-imide resin with good performance can be prepared by the reaction of p-phenylenediamine with Malay rosin monoyl chloride.

P-phenylenediamine and p-phenylenediyl chloride polycondensation polymer Kevlar, which is a high temperature resistant polymer liquid crystal resin, is now used in supersonic aircraft composites.

CAS:106-50-3

MF:C6H8N2

MW:108.14

EINECS:203-404-7

Synonyms:benzofurd ;C.I. 76076;C.I. Developer 13;C.I. Oxidation Base 10;c.i.developer13 ;c.i.oxidationbase10 ;C.I.OxidationBase10(76060) ;cideveloper13

Properties

Melting point:139 °C

Boiling point:267 °C(lit.)

Density 1.135 g/cm3 (20℃)

vapor density 3.7 (vs air)

vapor pressure 1.08 mm Hg ( 100 °C)

Flash point:156 °C

storage temp. 2-8°C

solubility Soluble in alcohol, chloroform, ether and hot benzene.

form Powder or Flakes

pka4.17(at 25℃)

Colour Index 76060

color White, gray, or purple to brown

PH RangeNonQ uorescence (3.1) to orange/yellow Q uorescence (4.4)

PH 9 (50g/l, H2O, 20℃)

Water Solubility 47 g/L (25 ºC)

Merck 14,7285

BRN 742029

Stability:Stable, but oxidizes when exposed to air. Incompatible with oxidizing agents. Store under inert atmosphere.

Use

Synthetic dyes and pigments

P-phenylenediamine is the intermediate of azo disperse dyes, acid dyes, direct dyes and sulfide dyes. Add 3% hydrogen peroxide to make it dark, and 5% iron chloride to make it brown. It has a strong affinity for keratin in hair, and its oxidation process is the fixation of color when dyeing hair. It is not only the most effective component of hair dye, but also the most potentially harmful substance to human health.

In the 1980s, according to the CI, 17 varieties were using p-phenylenediamine.

Sulfide yellow GC (CI 5310) originally used diphenylamine as an intermediate, because of carcinogenesis, xinbin county chemical plant has been successfully substituted with p-phenylenediamine. P-phenylenediamine derivatives 4.4' -diaminodiphenylurea and 4.4' -diaminodiphenylurea can also be used in other diazo dyes using diphenylamine instead of diphenylamine (synthesized from p-phenylenediamine, urea and thioneuria).

P-phenylenediamine can also be used to synthesize diazo condensation pigments, such as PR 166(Cr Scarlet R) and green sulfide dyes.

In addition, it can also synthesize better dyeing and pigment.

Synthetic resin

Kevlar 1414 (dupont Kevlar) is made from terephthalic acid or acylchloride by condensation with p-phenylenediamine. Domestic chenguang chemical research institute has an annual yield of 3-5 tons of resin pilot plant, yueyang general factory also has an annual output of 20 tons of resin pilot plant. In 1975, dupont also developed the polyimide resin nr-i50b2, which was formed by condensation of hexafluorotetraic acid and mixed aromatic diamine (4.4' -diaminodiphenyl ether, p-phenylenediamine and m-phenylenediamine). The polyamide-imide resin with good performance can be prepared by the reaction of p-phenylenediamine with Malay rosin monoyl chloride.

P-phenylenediamine and p-phenylenediyl chloride polycondensation polymer Kevlar, which is a high temperature resistant polymer liquid crystal resin, is now used in supersonic aircraft composites.

The reaction of p-phenylenediamine with phosgene can produce its diisocyanate (PPDI), so as to produce high crystallinity polyurethane. The product has excellent high temperature performance and can be used as thermoplastic and casting elastomer. Aromatic polyamide can be formed by the reaction of phenylenediamine with aromatic dicarboxylic acid, which can be used as reinforcing material for tires and v-tape, as reinforcing material for reinforced plastics, sports equipment, brake lining, etc., as well as other products with high strength and high modulus in demand.

Other related items of our company:

1. Basic Organic Chemicals

2. Inorganic Chemicals

3. Pharmaceutical Intermediates

4. Daily Chemicals

5. Active Pharmaceutical Ingredients

.png) Contact Now

Contact Now