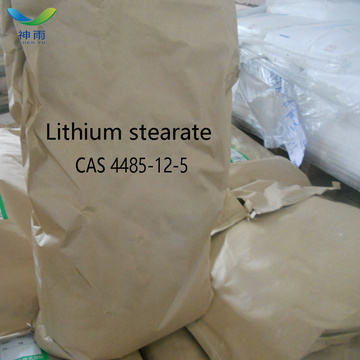

Chemical Auxiliary Agents

Chemical auxiliary agents can be used to change the chemical reaction rate (increase or

decrease) in the chemical reaction without changing the chemical equilibrium,

and the mass and chemical properties of the reactants are not changed before

and after the chemical reaction. According to statistics, about 90% of the

industrial processes use Chemical auxiliary agents, such as chemical,

petrochemical, biochemical, environmental protection and so on. There are a

wide variety of chemical auxiliary agents, which can be divided into

liquid and solid according to their state. The phase states of the reaction

system are divided into homogeneous and heterogeneous catalysts. The

homogeneous catalysts have acid, alkali, soluble transition metal compounds and

peroxide catalysts. Chemical auxiliary agents plays an important role in

the modern chemical industry, for example, the use of iron catalyst in the

production of synthetic ammonia, the production of vanadium catalyst in the

production of sulfuric acid, the polymerization of ethylene and the production

of three synthetic materials, such as butadiene rubber, use different

catalysts.

Chemical auxiliary agents Attention:

[

operation notice]

Closed

operation, local exhaust. Prevent steam from leaking into the air of the

workplace. Operators must undergo special training and strictly abide by the

rules of operation. It is recommended that operators wear self-priming filter

respirators (semi masks), wear chemical safety glasses, wear protective clothing

and wear rubber gloves. Keep away from fire and heat sources. Smoking is

strictly prohibited in the workplace. The use of explosion-proof ventilation

systems and equipment. Before welding liquid and steam, welding and cutting

operations can not be carried out. Avoid smoke. Avoid contact with oxidants.

Equipped with corresponding varieties and quantities of fire fighting equipment

and leakage emergency handling equipment. The empty container may remain

harmful.

[storage

notice]

Store in

a cool, ventilated storeroom. Stay away from fire and heat. Prevent direct

sunlight. Keep the container seal. It should be kept separately from the

oxidizing agent and avoid the mixture. Equipped with the corresponding variety

and quantity of fire equipment. Emergency handling equipment and suitable

storage materials should be provided in the storage area.

.png) Contact Now

Contact Now